All About: Submersible Well Pumps

Pat Scheper

In previous blogs, we have talked about wells and the various plumbing aspects of it, and following in that trend, today we will look at the submersible well pump.The most important, and most obvious, component to a submersible well system is the submersible well pump.

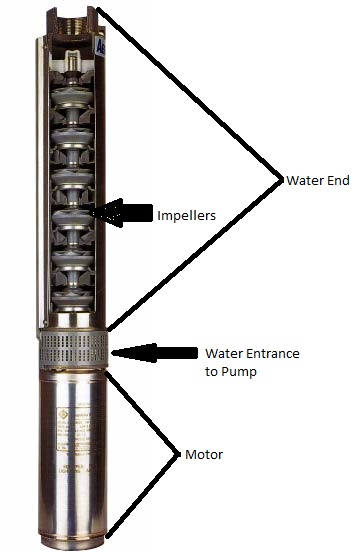

A submersible well pump has two components- the motor and the water end. In general, homes in Central Maryland have well pumps with motors that range from ½ horsepower to 1½ horsepower. The motors are made of stainless steel and are about 4” in diameter and 12”-18” long. On top of the motor sits the water end. Like the motor, it too is comprised of stainless steel and is also approximately 4” in diameter and 12”-18” in length.

Inside the water end is a shaft that is turned by the motor and sticks down into it. Inside the water end and connected to the shaft are a series of impellers that spin as the shaft spins. Finally, in between the motor and the water end is a gap of about 2” that lets water be sucked into the water end.

So how does the submersible well pump work?

So how does the submersible well pump work?

Well the submersible well pump is connected to a pipe and wire (electric source) and stuck down into the well. The pump sits 10’-20’ off of the bottom of the well to avoid sucking up sediment/dirt in the well. The electric wire coming down the pump is connected to the motors wire and then we melt a plastic tube over the connection to make it water tight.

The pump head is connected to the pipe in the well and secured with clamps so that it doesn’t become disconnected. The wire extends all the way up the well, exits the well casing at the top and is buried underground where it goes into the house to connect to the electric panel and pump controller. The pipe extends all the way up the well casing and exits the well through the side of the casing about 3’ below ground (below the frost level). It exits with a special fitting that is called a pitless adapter. This adapter has 2 parts. The first is on the outside of the well connected to an underground pipe that goes into the house and connects to the plumbing system. The second piece goes inside of the well and is connected to the pipe coming up from the pump.

The two pieces connect to each other through a hole in the well casing, and when connected, form a water tight seal that allows nothing from the outside of the well to enter in and contaminate the system.

Soo… when the well pump is told to turn on the motor spins the shaft and the shaft turns the impellers. The impellers have fins on them so as they turn they create an upward driving force, which sucks water in through the opening between the water end and the motor, which in turn forces the water upwards through the well pipe in the casing. The water goes up the well pipe, through the side of the casing through the pitless adapter, through the underground pipe into the home and into the plumbing system. And just like that, we have water!

So how does the well pump know when to turn on? That is the job of the well tank, which we will discuss in next weeks’ blog.

A Note on Sizing: We mentioned that there are different sized motors and water ends, and we know you are wondering just how we determine the size of each. As we said above, motors come in different horsepowers. Water ends come in different gallons per minute ratings. The more impellers inside of the water end the more water it can pump and the higher gallons per minute rating it receives. They generally range in ratings of 5-25 gallons per minute. Different sized motor and water ends can pump different amounts of water.

To make things more complicated, the amount of water any given pairing can pump also depends on well depth, water levels, distance of a well from the house, well tank size, number of plumbing fixtures and the list goes on.

All of this information is used to look up motor/water end pairings on a series of graphs and charts provided by the manufacturer’s engineers to tell us exactly which well pump we need to install in your well. Simple, we know. But rest assured that all our technicians know how size a well pump and that Apple Plumbing will make sure that all you have to do is turn on the faucet!