How Does a Well Tank Work?

Pat Scheper

For this blog, let’s dive on in and discuss another type of pump you may have in your home!Your pump tank, or well tank, is the blue steel tank in your home. It is generally in your basement or in a utility closet and has the well pipe from your well pump connected on one side and the cold water main to your house connected on the other side. This is how your pump tank works:

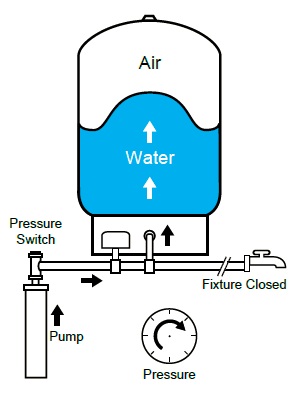

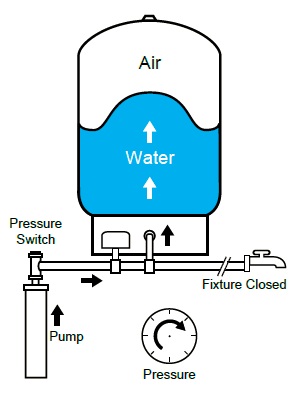

Inside of that tank are two bladders that sit on top of each other. The top bladder is completely sealed and filled with air. The air pressure in the tank varies for the house, but the standard is when the tank has no water in it we pre-charge the air pressure to 38psi. The bottom bladder is a water reservoir that is connected to the plumbing system. When we first turn on the well pump it fills the bottom bladder of the well tank with water. As the tank fills up the top bladder filled with air is contracted and as a result the air pressure builds.

Inside of that tank are two bladders that sit on top of each other. The top bladder is completely sealed and filled with air. The air pressure in the tank varies for the house, but the standard is when the tank has no water in it we pre-charge the air pressure to 38psi. The bottom bladder is a water reservoir that is connected to the plumbing system. When we first turn on the well pump it fills the bottom bladder of the well tank with water. As the tank fills up the top bladder filled with air is contracted and as a result the air pressure builds.

On the outside of a tank there is a pressure switch which measures the amount of pressure in the well tank. When the well pump has filled the tank to the point where the top bladder has contracted to 60 pounds of pressure the pressure switch cuts off electric to the pump and water stops flowing.

Let’s now say someone in the home goes to take a shower. When we turn on the water to the house the pump doesn’t immediately turn on but rather the pump tank delivers the first wave of water (pun intended!). When we open up the shower faucet we are literally relieving the pressure from the well tank and the air in the top of the tank pushes the water in the bottom bladder (and the plumbing pipes) out through the shower faucet.

As this happens, the pressure in the tank decreases. When the pressure reaches 40psi the pressure switch sends electric down the pump which turns on and continues pumping water into the plumbing system. When you finish your shower and shut off the water the pump keeps pumping water into the pump tank until it reaches 60psi and then shuts off. The next time you turn on water the process repeats itself and we call that the pump cycle.

A few “fun” pieces of information:

We call the amount of time that a fully charged well tank can deliver water before the pump turns on is called the drawdown time. The larger the reservoir in the bottom of the tank (it varies between about 10 different models of tanks), the greater the drawdown time, the less frequent the pump has to turn on and off to deliver water during its life, which all results in a longer pump life.

We also size well tanks so that the time it takes for a well pump to pump water into a well tank to increase pressure from 40 psi to 60psi is no less than 1 minute (it is a slightly complicated formula that deserves a full lesson on its own)! The reason we need a specific run time is that well pumps motors are designed to run for at least 1 minute before turning off or else it overheats the motor and damages it. A shorter run time is what we call “cycling”. This also occurs when the air bladder ruptures in the top of the tank and the pump turns on every time a faucet opens.

And there ya go, all about your well tank!

So how does the submersible well pump work?

So how does the submersible well pump work?

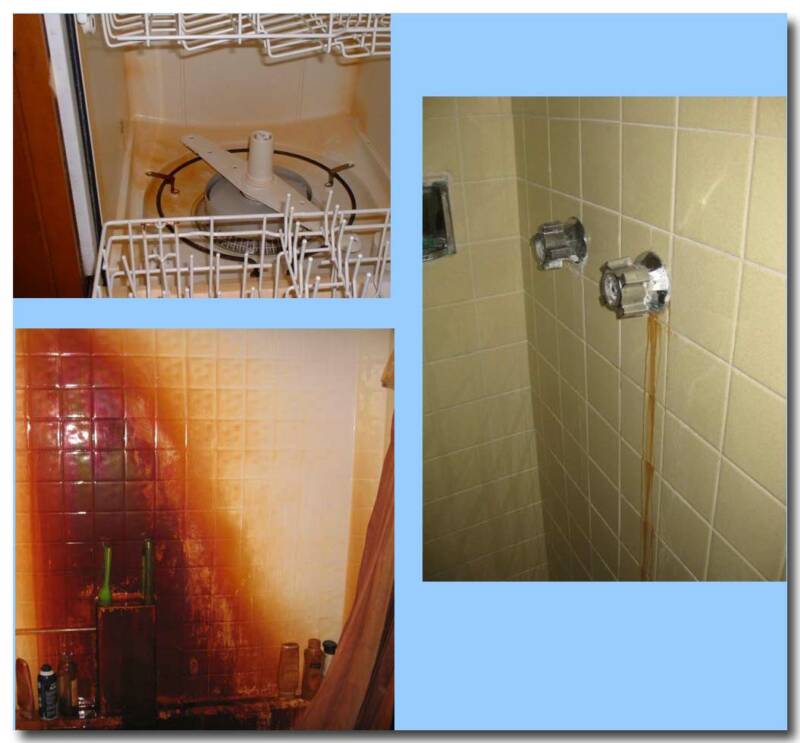

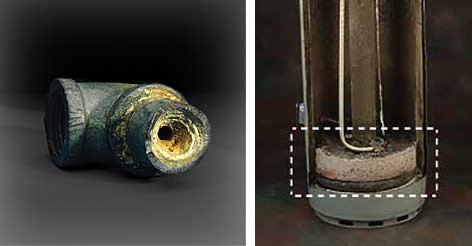

Hard water builds up and forms deposits that clog up your pipes. These deposits, of course, restrict the flow of your water and can corrode pipes, dishwashers and washing machines as well as the various pieces of plumbing equipment you have in your home. Maybe most importantly, hard water causes scale and sediment buildup in your water heater (as pictured in the second image) decreasing heating efficiency, gallon capacity, and the life expectancy of the water heater.

Hard water builds up and forms deposits that clog up your pipes. These deposits, of course, restrict the flow of your water and can corrode pipes, dishwashers and washing machines as well as the various pieces of plumbing equipment you have in your home. Maybe most importantly, hard water causes scale and sediment buildup in your water heater (as pictured in the second image) decreasing heating efficiency, gallon capacity, and the life expectancy of the water heater.

TDS is like putting salt into water, as you add the salt it disappears into the water. Pure water would have a TDS of 0ppm. Typical well systems have a TDS anywhere from 50 to 940ppm (our office’s personal record). On average, our customers well water TDS is 150-250ppm.

TDS is like putting salt into water, as you add the salt it disappears into the water. Pure water would have a TDS of 0ppm. Typical well systems have a TDS anywhere from 50 to 940ppm (our office’s personal record). On average, our customers well water TDS is 150-250ppm.