Everyone who has hot, running water in their home today has some type of water heater they depend on. As the name indicates, the water heater’s primary function is to provide a household with hot water in which to bathe, wash dishes, do laundry, and a host of other every day activities. Because water heaters are such important features, the rules, codes and safety regulations surrounding them are constantly being evaluated, updated and improved. The next series of changes will begin early this spring. As a homeowner, it’s important to be aware of any regulation changes that could affect your heater, when the time comes to install a new one. Therefore, Apple Plumbing has done our research and below, we’ve outlined all future changes in manufacturing coming in April 2015.

Briefly, the department of Energy (DOE), as part of the National Appliance Energy Association Act (NAECA), issued new energy efficiency mandates in 2010. In 2015, those mandates will be applied and all water heater manufacturers will be required to comply. The update, effective starting April 16, 2015, will require higher Energy Factor (EF) ratings on almost all residential gas, electric, oil and tankless gas water heaters. The Energy Factor is the ratio of useful energy output from the water heater to the total amount of energy delivered to the water heater. The higher the EF is, the more efficient the water heater.

It is important to note that these changes are manufacturer requirements and not homeowner, wholesaler, or plumber requirements. This means, that starting 4/16/15, all water heater manufacturers will have to cease production of heaters designed to comply to current codes, and begin making them to meet the new rules. This does not mean that homeowners must replace their water heaters, or wholesalers have to stop selling all already-manufactured water heaters that don’t comply, nor does it mean that plumbers have to stop installing them. We can continue to install existing inventory until they’re gone, at which time only water heaters meeting the new EF ratings will be available for purchase. Parts for the currently existing models should continue to work for the updated units, as the primary change will be seen in tank sizing and in new, additional equipment.

If you know the type of heater you have, you can review the information for it below and how the changes might affect you.

[expand title="Residential Gas Water Heaters Less than 55 Gallons"]

- The Energy Factor has been increased from .55 to .675

- Gas water heaters can no longer have a standing pilot, all water heaters will need to plug into an electrical outlet for electronic ignition

- Due to the increase in heat output, more insulation will be needed. Because of this, the size of the heater will likely have to expand. It is estimated that the new heaters will be 1”-2” taller, and 2” wider in diameter.

- How does all this affect you? If your heater is installed in a tight corner, small closet or other narrow space, when it’s time to replace your heater, the technicians performing the work could run into problems trying to fit a larger heater in the small space, and may end up needing to move it to a new location, which would likely require additional work to the piping and water supply. A licensed electrician may be needed to install a new electrical outlet next to your water heater.

- Other Options

- Reduce the size of the heater, increase the temperature in the tank, and put a mixing valve to mix cold water in with the hotter water as it comes out of the tank. This increase the effective gallon capacity of the smaller heater to your original size

- Tankless water heater

[/expand]

[expand title="Residential Gas Water Heaters Greater Than 55 Gallons"]

- The Energy Factor has been increased from .55 to .8012

- Gas water heaters can no longer have a standing pilot, all water heaters will need to plug into an electrical outlet for electronic ignition

- Due to the increase in heat output, more insulation will be needed. Because of this, the size of the heater will likely have to expand. It is estimated that the new heaters will be 1”-2” taller, and 2” wider in diameter.

- Additional heating tubes, bigger flues, and other venting equipment will be required to heat the water more efficiently

- A condensate drain would most likely need to be installed to dispose of extra condensate being emitted.

- How does all this affect you? If your heater is installed in a tight corner, small closet or other narrow space, when it’s time to replace your heater, the technicians performing the work could run into problems trying to fit a larger heater in the small space, and may end up needing to move it to a new location, which would likely require additional work to the piping and water supply. Additional work would also be required to install the necessary venting equipment. A licensed electrician may be needed to install a new electrical outlet next to your water heater.

- Other Options

- Reduce the size of the heater to below 55 gallons, increase the temperature in the tank, and put a mixing valve to mix cold water in with the hotter water as it comes out of the tank. This increase the effective gallon capacity of the smaller heater to your original size

- Tankless water heater

[/expand]

[expand title="Residential Electric Water Heaters Less Than 55 Gallons"]

- The Energy Factor has been increased from .93 to .96

- Due to the increase in heat output, more insulation will be needed. Because of this, the size of the heater will likely have to expand. It is estimated that the new heaters will be 1”-2” taller, and 2” wider in diameter.

- How does all this affect you? If your heater is installed in a tight corner, small closet or other narrow space, when it’s time to replace your heater, the technicians performing the work could run into problems trying to fit a larger heater in the small space, and may end up needing to move it to a new location, which would likely require additional work to the piping and water supply.

- Other options

- Reduce the size of the heater, increase the temperature in the tank, and put a mixing valve to mix cold water in with the hotter water as it comes out of the tank. This increase the effective gallon capacity of the smaller heater to your original size

[/expand]

[expand title="Residential Electric Water Heaters Greater Than 55 Gallons"]

- The biggest Energy Factor change is seen in electric heaters larger than 55 gallons.

- 65 gallons: Increase from .88 to 1.98

- 80 gallons: Increase from .86 to 1.97

- 120 gallons: from 1.00 to 1.92

- The only current technology to achieve an energy factor over 1.00 is heat pump technology, likely integrated on top of the heater unit. Water heaters with a heat pump use the refrigeration cycle and air in your home to greatly increase the efficiency of the water heater.

- This will require 700-1,000 cubic feet of space.

- The ambient room temperature will affect the performance of the pump, as it draws energy from the heat in the air.

- A cooler room means the heater will take longer to heat the water in the unit, versus a warmer room which will have a greater energy supply from which the pump can draw.

- The increased heat will create condensate, so a drain will need to be installed for disposal.

- How does this affect you? The heat pump technology may require regular servicing such as cleaning and changing of filters. The pump can be noisy, so the noise level in the room your water heater is in will increase and consideration as to what rooms are near the water heater may need to be given. Additional work will need to be performed by the technicians installing your new water heater, to also install the heat pump technology and new drain.

- Other Options

- Reduce the size of the heater to below 55 gallons, increase the temperature in the tank, and put a mixing valve to mix cold water in with the hotter water as it comes out of the tank. This increase the effective gallon capacity of the smaller heater to your original size

- Install 2 smaller heaters, such as 40 gallon electrics, that do not require heat pump technology

[/expand]

[expand title="Other Water Heaters"]

- The Energy Factor will increase from .53 to .62 in the 30 gallon size and increase from .50 to .59 in the 50 gallon size.

- Due to more heat transfer technology needed for oil-fired heaters because of the Energy Factor increase, there is the possibility the unit will be much heavier than the current standard model.

- Due to the increase in heat output, more insulation will be needed. Because of this, the size of the heater will likely have to expand. It is estimated that the new heaters will be 1”-2” taller, and 2” wider in diameter.

- How does this affect you? If your heater is installed in a tight corner, small closet or other narrow space, when it’s time to replace your heater, the technicians performing the work could run into problems trying to fit a larger heater in the small space, and may end up needing to move it to a new location, which would likely require additional work to the piping and water supply.

- Residential Gas Tankless

- No Energy Factor requirement exists, so an EF Rating of .82 will be implemented

- To our knowledge all tankless water heaters currently meet this rating, those few that don’t will undergo technology changes to comply

- Residential Electric Tankless

- No Energy Factor requirement exists, so an EF Rating of .93 will be implemented

- To our knowledge all tankless water heaters currently meet this rating, those few that don’t will undergo technology changes to comply

[/expand]

After reading all the information pertaining to your model of water heater- the changes coming and what it could mean for you, you’ll need to consider what you might do to prepare. The greatest advantage you have in knowing this information ahead of time is that you have the opportunity to be proactive. Rather than waiting for your heater to suddenly spring a leak and have to hire a plumber out right away to take care of the leak and all the possible headaches that could come with moving the heater to a new location, adding in new piping and other necessary technology, you can plan ahead and get the work done before it becomes an emergency.

We know this is a lot of information to take in. We want to reassure you that Apple Plumbing is here for you when the time does come, and that we are keeping ahead of the curve by studying all changes and being ready to answer any questions you may have. Come April 16 and in the months to follow, we will be knowledgeable and equipped to do what is necessary in replacing your heater to ensure it fits well, is installed properly, and will continue giving you and your home the hot water you need.

In late June, Apple Plumbing & Heating, Inc. installed a new, high efficient hot water system for The Hill Family Center Y.The following photos and description details the work that was done, the planning that went into it and how this installation helped the Y reduce their carbon footprint.

In late June, Apple Plumbing & Heating, Inc. installed a new, high efficient hot water system for The Hill Family Center Y.The following photos and description details the work that was done, the planning that went into it and how this installation helped the Y reduce their carbon footprint.

By Wednesday afternoon that week, all of our techs had put in 40 hours and were into overtime. I’ve been in the plumbing service business 46 years and I have NEVER seen anything like that. And it continued on for weeks. Weather forecasters are predicting a “colder than average” winter for the East Coast this year. Because of an early snow in the Siberian Dessert we stand a good chance for another Polar Vortex. Dang!

So, there are a few things you need to consider with your plumbing system to prepare for the possible frigid weather this winter:

By Wednesday afternoon that week, all of our techs had put in 40 hours and were into overtime. I’ve been in the plumbing service business 46 years and I have NEVER seen anything like that. And it continued on for weeks. Weather forecasters are predicting a “colder than average” winter for the East Coast this year. Because of an early snow in the Siberian Dessert we stand a good chance for another Polar Vortex. Dang!

So, there are a few things you need to consider with your plumbing system to prepare for the possible frigid weather this winter: If you have plumbing on an overhang, you need to make sure the piping in the overhang is properly insulated, that the building insulation is properly installed, and that any cracks or openings in your siding and exterior finish are sealed.

If you have plumbing on an overhang, you need to make sure the piping in the overhang is properly insulated, that the building insulation is properly installed, and that any cracks or openings in your siding and exterior finish are sealed.

Can you believe it? The holiday season is upon us. There are holiday displays going up in stores, Christmas themed music being played by a few excited folks, and holiday gatherings are in the process of being planned.

If you’re the designated person in your family to host the Thanksgiving, Christmas, Hanukkah, New Years Eve or any other holiday get-together this year, we’ve got a few reminders for you in helping you get your house holiday-ready!

Can you believe it? The holiday season is upon us. There are holiday displays going up in stores, Christmas themed music being played by a few excited folks, and holiday gatherings are in the process of being planned.

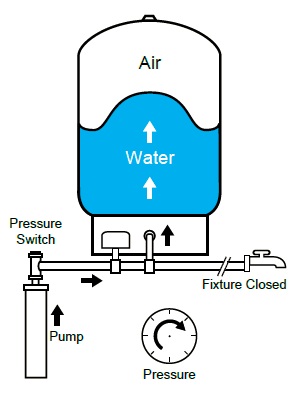

If you’re the designated person in your family to host the Thanksgiving, Christmas, Hanukkah, New Years Eve or any other holiday get-together this year, we’ve got a few reminders for you in helping you get your house holiday-ready! Inside of that tank are two bladders that sit on top of each other. The top bladder is completely sealed and filled with air. The air pressure in the tank varies for the house, but the standard is when the tank has no water in it we pre-charge the air pressure to 38psi. The bottom bladder is a water reservoir that is connected to the plumbing system. When we first turn on the well pump it fills the bottom bladder of the well tank with water. As the tank fills up the top bladder filled with air is contracted and as a result the air pressure builds.

Inside of that tank are two bladders that sit on top of each other. The top bladder is completely sealed and filled with air. The air pressure in the tank varies for the house, but the standard is when the tank has no water in it we pre-charge the air pressure to 38psi. The bottom bladder is a water reservoir that is connected to the plumbing system. When we first turn on the well pump it fills the bottom bladder of the well tank with water. As the tank fills up the top bladder filled with air is contracted and as a result the air pressure builds.